COVID-19 has changed the supply chain landscape forever. Supply chain disciplines, also known as the core best practices, have not withstood the impact of the ongoing pandemic. Companies have completely changed how they operate and are now preparing to bolster their supply chain to provide the best customer service.

One of the disciplines that has been getting the most attention has been supply chain compliance.

Verisk 3E defines supply chain compliance as an umbrella term that describes the practice of managing the ever-evolving business in which access to health, safety, environmental risks of raw materials and goods become a critical component of various transactions and supplier/customer relationships. Not having a compliant supply chain increases a business’s chance of facing a broad range of uncertainties within the supply chain that affects the bottom line and consumer satisfaction.

Rapid changes to the global supply chain landscape have triggered an enormous wave of uncertainty propelling savvy companies to spend more money to achieve compliance assurance from their suppliers. Companies have realized that most of the tried and tested ways of evaluating risk and success are redundant and based on false assumptions. Mitigating operational, business, and legal risk in this dynamic compliance landscape requires companies to increase certainty, minimize execution risk, and communicate seamlessly with their suppliers and customers. The best performing supply chains build transparency across all their stakeholders, allowing them to build effective strategies based on real-time data.

For companies to succeed in the post-COVID era, they need an effective supply chain compliance strategy that reduces risk within the supply chain. Understanding what your products are made of, how well your factories are performing, and mapping lead time against quality of goods across different vendors are just examples that can serve as effective building blocks for a robust compliance strategy. All this data provides actionable insights across your supply chain’s length and breadth, enabling companies to make data-backed decisions.

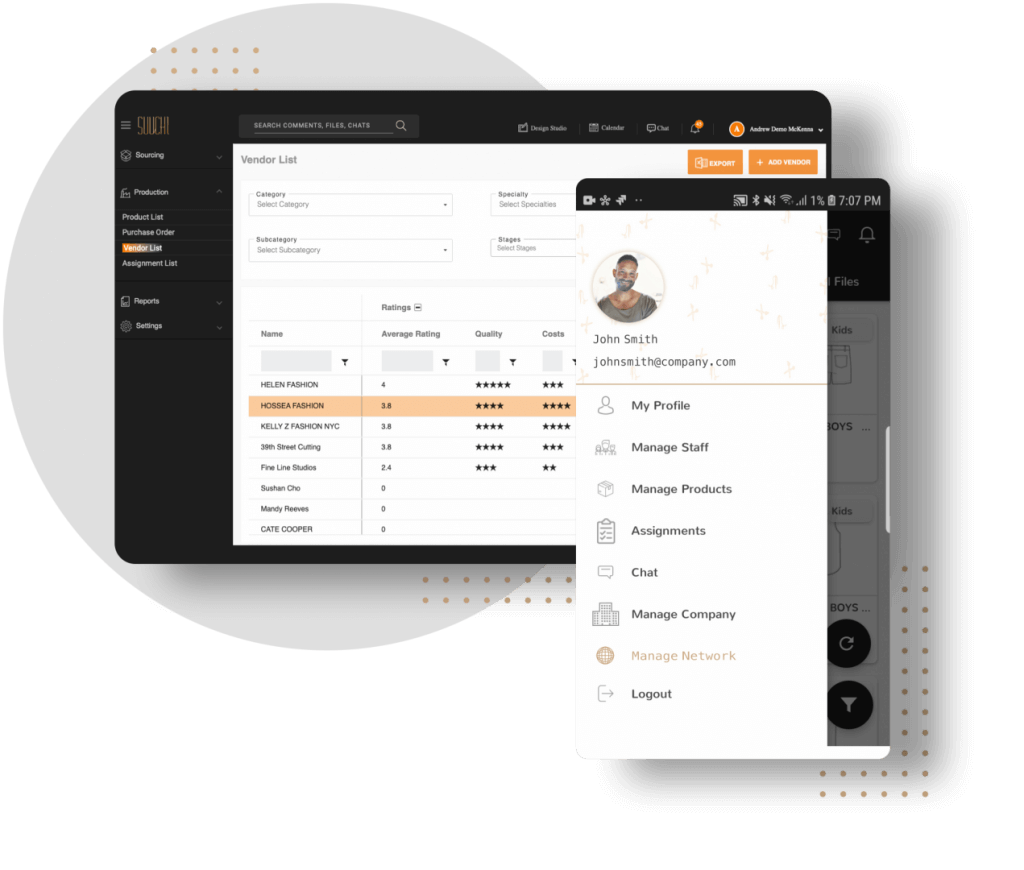

The days of one-dimensional compliance are long gone in today’s liner world, and outdated solutions are no longer enough to support sustainable growth. The need for compliance exists in various parallels and intersecting planes within a company’s supply chain. Therefore a compliance solution is required that stretches across the entire length of your supply chain. That’s where the Suuchi GRID comes in – the GRID is a digital wrapper across the operating lifecycle that allows you to build a repository of information across your suppliers, factories, customers.

This nested information allows you to consolidate your supply chain and reduce redundant, manual tasks to bog down your team. Through a single platform, the GRID enables companies to create unique profiles for each supplier in their network to store information such as certifications, compliance documents, and ratings on critical metrics. By utilizing this nested compliance approach and creating a reusable data asset from the collected and created information, companies can create a robust supply chain strategy that puts compliance first, no matter what disruptions shock the value chain next.